Blog

AutomotivePIM: Real-time data with

the new TecDoc IDP interface

Coordinating different data streams is a major challenge for many companies. Particularly when data and information is provided through multiple internal and external sources.

The automotive aftermarket brings its own challenges due to its multi-layered networking of different entities – however it doesn’t have to stop there: Thanks to new approvals from TecAlliance, Bertsch Innovation is one of the first to create a bidirectional interface for AutomotivePIM enabling new means of data management.

The innovative TecDoc IDP interface

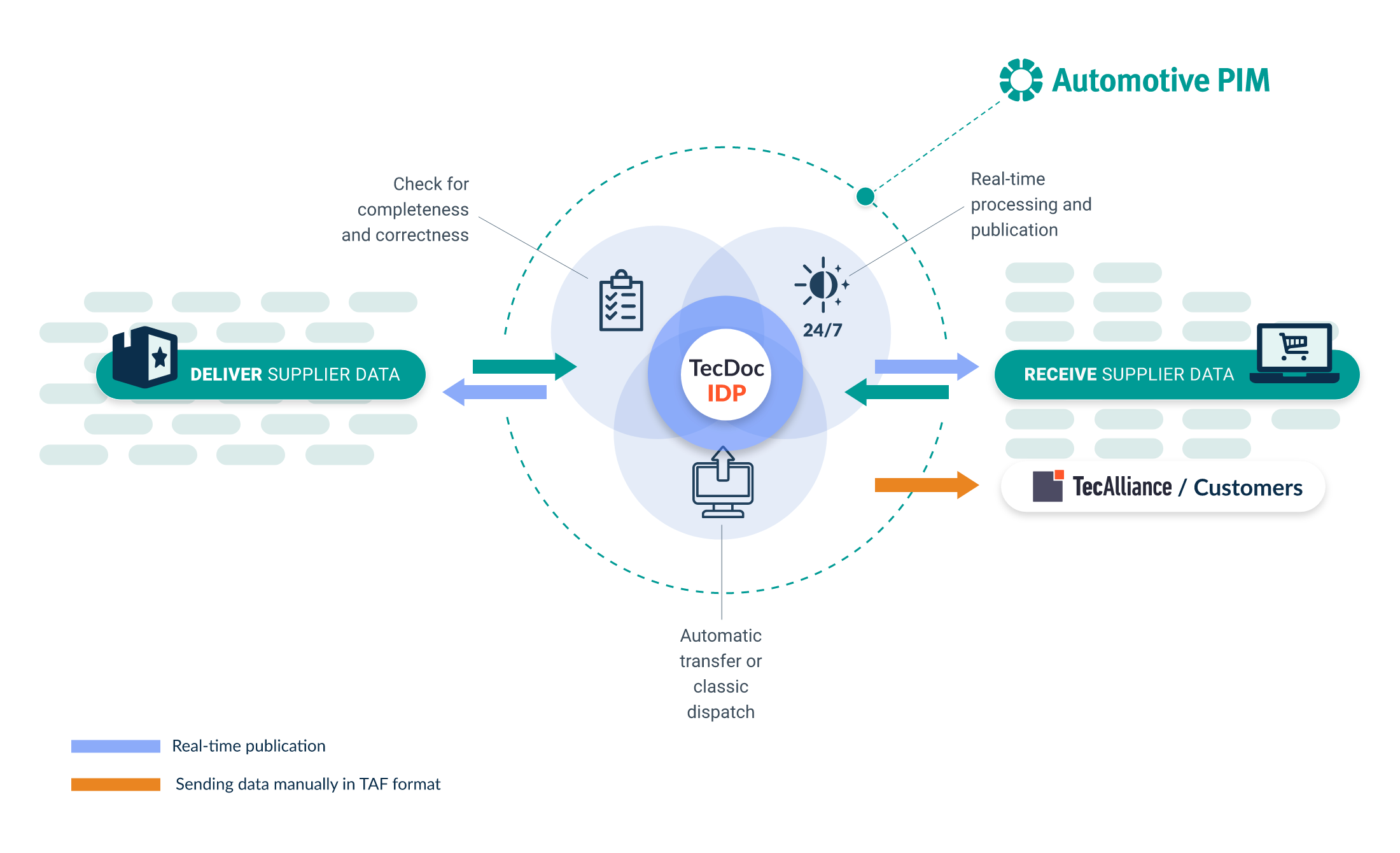

IDP – Instant Data Processing – is the core element of this interface: immediate data processing in real time.

This makes the TecDoc IDP interface, embedded directly in the PIM system, a game-changing solution for connecting AutomotivePIM and TecAlliance.

The system works in both directions thanks to its bidirectional connection and provides two elementary features.

1. Data transfer:

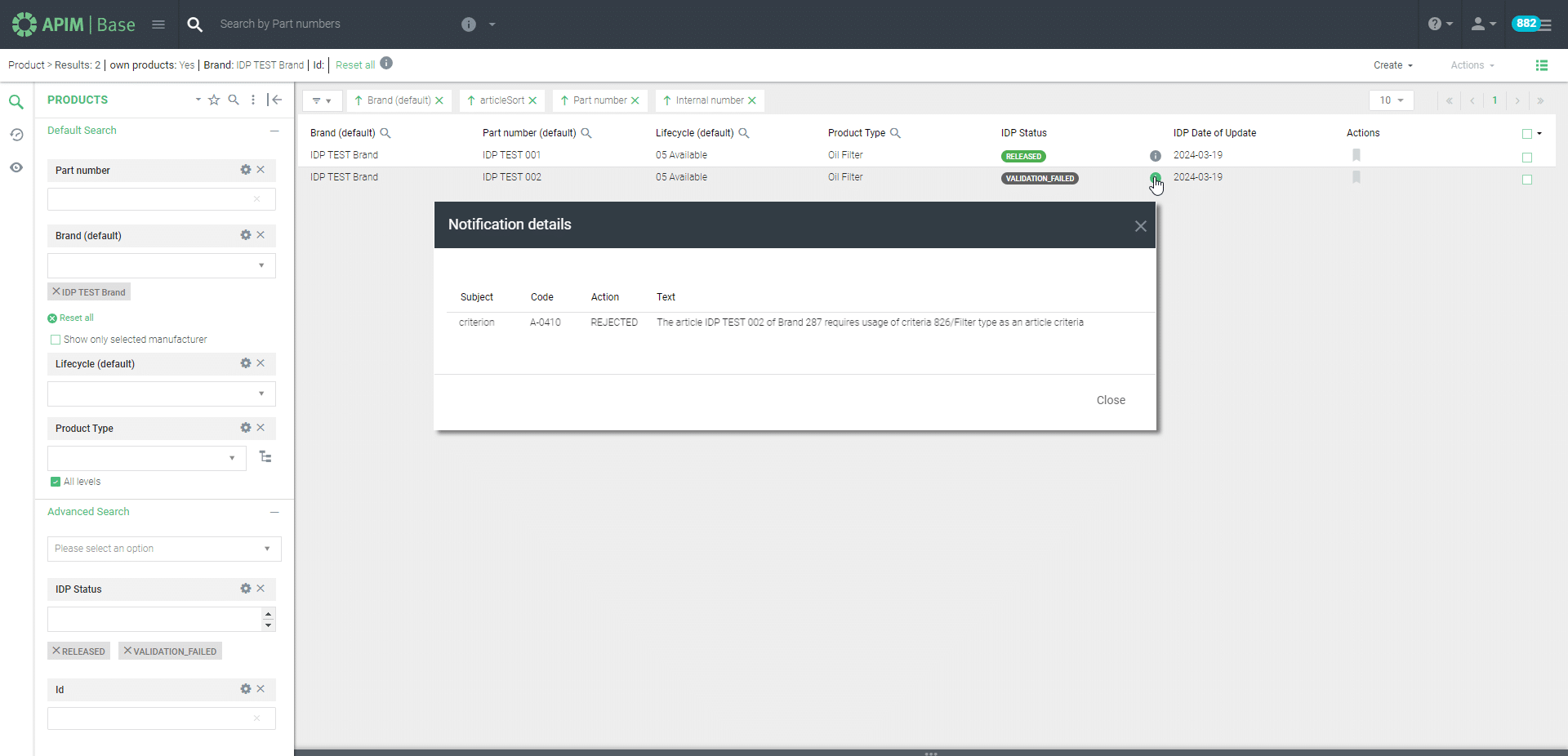

All relevant data can be transferred to TecAlliance and subsequently checked for completeness and correctness. If errors, blanks or other discrepancies are detected in the transmitted data records during this check, the corresponding error messages are transferred directly to AutomotivePIM and can be viewed, evaluated and corrected individually.

2. Data publication:

The second highlight involves the publication of product data itself: By using the TecDoc IDP interface, product data, links and digital assets are validated and published in real time.

This facilitates the reoccuring and time-consuming data submission due every month, saving internal resources and boosting data quality. AutomotivePIM checks your data reliably and any necessary corrections can be made before the final publication to TecAlliance.

Parallel to the interface, the option of generating data in classic TAF format in AutomotivePIM and sending it manually to TecAlliance or customers is still available.

Automated and intelligent data management

AutomotivePIM provides a wide range of options to make working with vehicle data and product properties significantly smoother.

Especially automation rules for maintaining and updating product information and associated links, such as individual vehicles or engines, build the core of the system.

The new IDP interface provides an easy way to set up rule-based automation of various processes, significantly optimizing resources. This applies to a variety of aspects. For example, relationships and attributes for different products are able to be compared with one another. For product relationships linked via many different nodes and individual product elements in particular, this is a time-efficient advantage.

This element also allows properties and links from an initial product to be:

This results in the following advantages:

In addition, the system offers the possibility of analyzing OE data (original equipment data provided by TecAlliance in TAF or ACES format, for example) and utilizing it in market analyses to optimize the company’s own product range development.

Get more from your AutomotivePIM

The integration of the TecDoc IDP interface into AutomotivePIM offers a wide range of strategic advantages that go beyond the purely technical aspects of real-time data transfer.

Automation of workflows, real-time data transfer and valuable insights into actual market activity mean that AutomotivePIM users now benefit from:

Read all the facts worth knowing about AutomotivePIM from Bertsch Innovation in the following fact sheet:

The TecDoc IDP interface is another fundamental building block for automating data transfer. This makes AutomotivePIM a valuable resource for companies in the automotive aftermarket looking to take their product management strategy to the next level.

Are you also facing the task of supplying your product information to TecDoc and would like to benefit from this automation? We look forward to hearing from you.

Highlighted Whitepaper

ePaper: Automotive Aftermarket

Download onze automotive aftermarket e-paper en kom meer te weten over de dagelijkse uitdagingen van fabrikanten, werkplaatsen en serviceproviders.

Samen meer bereiken

Wij geloven in de waarde van samenwerking en uitwisseling. Dit geldt zowel de projecten met onze klanten, waaruit we veel waardevolle inzichten genereren voor onze productontwikkeling, als voor ons groeiende partnernetwerk, waarmee we onze klanten ondersteunen bij hun digitalisering.